Surface treatment tailored to the application

MELTEC provides surface treatment after etching in order to make products with additional functionality. As at etching manufacturer with abundant knowledge of metal processing, we offer the optimal process for the required applications and materials while maintaining dimensional precision.

Example applications: Optical parts, automobile parts, medical devices, sensing devices, measuring devices, and others.

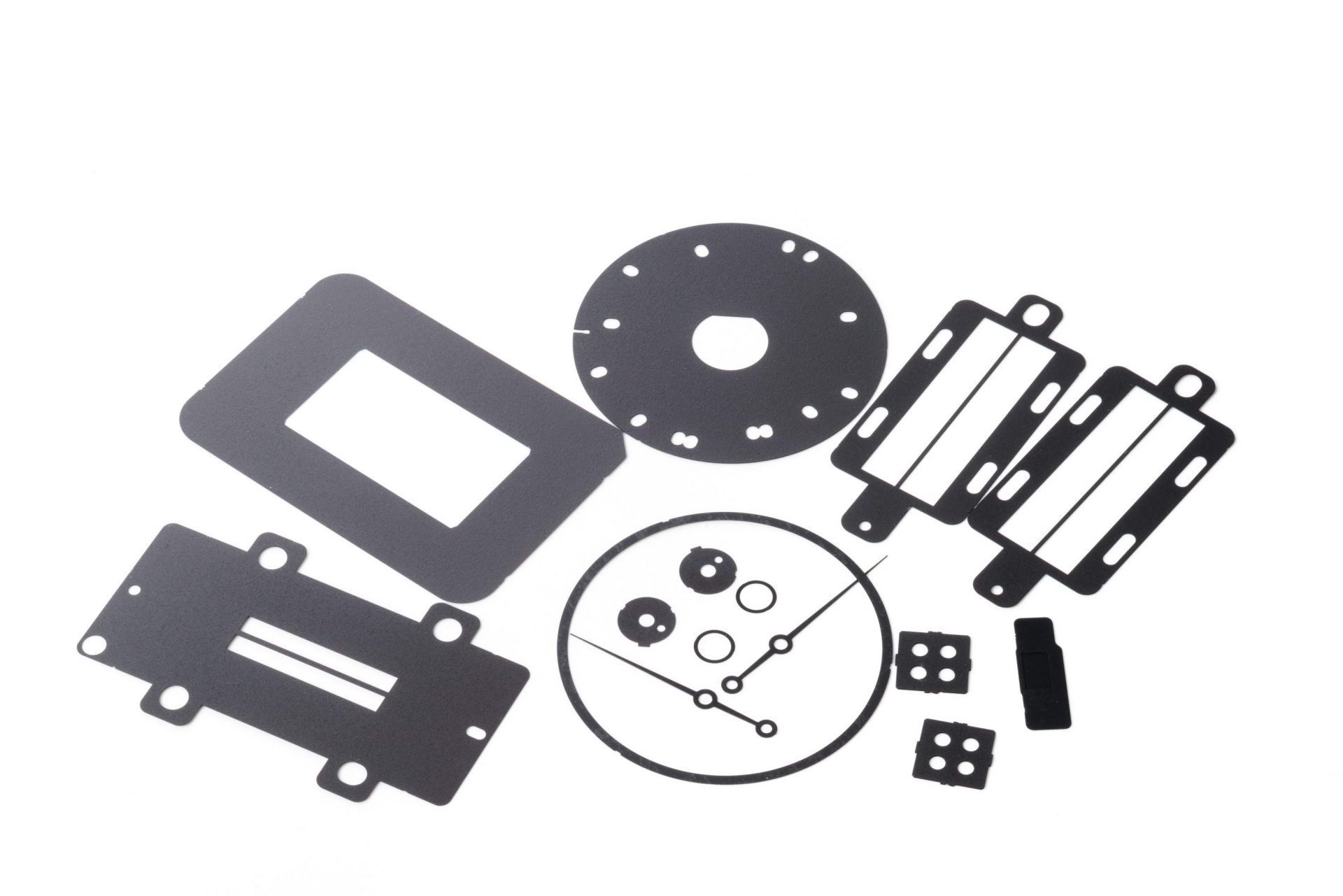

Additional functions such as anti-glare, anti-reflection, and anti-rust can be applied to various metals such as stainless steel. Dimensional precision of the etched parts can be maintained even after black treatment. You can choose treatment methods such as “oxide film coating type” and “plating type” to best fit the application and material properties.

Types of black surfacing treatment: Low-temperature chromium-plated, black oxide film, black coating, PARKELIZING, DRILUBE, DLC coating, among others.

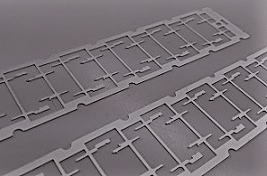

Examples of processing

| Reflectance | Dimension change | Electroconductivity | |

|---|---|---|---|

| MELTBLACK Ex | 2% | +0.001~+0.002 | ○ |

| SUPER MELTBLACK | 1% | +0.003~+0.007 | × |

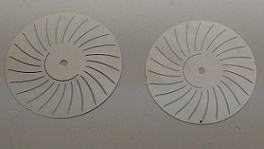

Functions such as electroconductivity and decorativeness can be added to all sorts of metals by surface treatments such as electropolishing, sandblasting, anodically oxidized coloring, alumite treatment, and plating in metals such as gold or silver.

Black surface treatment of SUS

Anti-reflection is added to SUS by treatments such as low-temperature chromium plating or black oxide film.

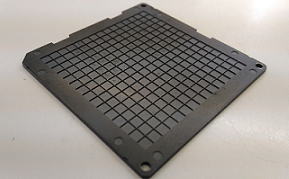

DLC coating

Excellent in wear-resistance, low-friction, and anti-corrosiveness. Used for industrial parts and home appliances.

Matte nickel plating

Nickel surface plating without glossiness. Black nickel also available.

Electropolishing

Smoothens and adds glossiness to a metal surface. Polishing without creating any deformed, burnt, or dirty layers. Chemical polishing is also available.

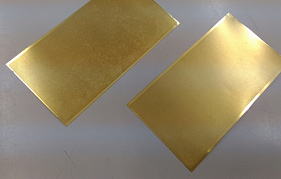

Gold plating

Plating can be done on both the surface and end faces of metals. Partial plating is also available.

Silver plating

Plating can be done on both the surface and end faces of metals. Partial plating is also available.