MELTEC’s micro hole technology can create meshes and filters from metal or resin for a variety of applications.

High-precision and complex shapes can be created.

Secondary processing such as bending and stamping after etching can be done in house for one-stop production.

Applications for use include electrical/electronic components, automobile parts, medical devices, and food processing.

Applications

We process a wide range of products from metal filters for the automotive industry to coffee filters for commercial machines in the fields of electronics and electrical parts, automotive parts, medical equipment, and food processing.

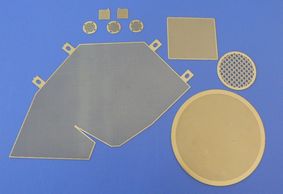

1. Etching

- SUS, copper and other various metals can be processed.

- Shapes can be freely designed, in contrast to stamped products such as punched mesh.

- Additional processing (bending, diffusion bonding and surface treatment) is available.

Reference example: SUS304, t=0.05: Minimum hole dia. 0.08, minimum pitch 0.13

Examples of etched products

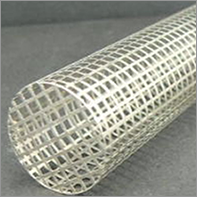

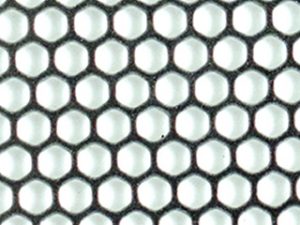

SUS honeycomb mesh

Honeycomb structure with a high aperture ratio can be made for various applications.

t=0.05, minimum hole dia. 0.08

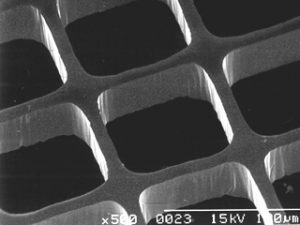

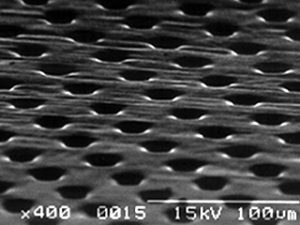

Micro hole mesh

Mesh with ultra-small diameter holes of 0.005mm

t = 0.023mm, etc.

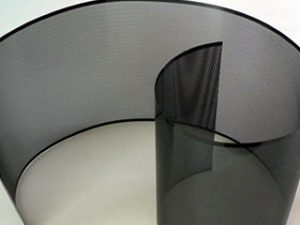

Etching + rolling

Etched mesh can undergo secondary processing such as bending and stamping.