The electroforming process utilizes electrochemical reactions, similar to electroplating.

It reproduces the shape of the master shape by electrodepositing metallic ions onto the surface of the master and excels in dimensional precision and transferability.

MELTEC’s electroforming is “Nickel electroforming” combined with photolithography technology.

It achieves a high level of dimensional precision which is not possible by the photoetching process.

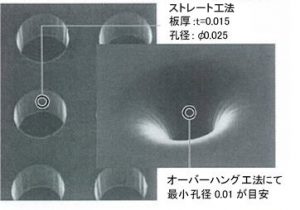

It uses straight processing for high-definition patterns and an overhang processing for miniscule holes.

Technical features

- Creates components with high-definition and high-precision.

- Vertical cross sectional shape of through hole by straight processing.

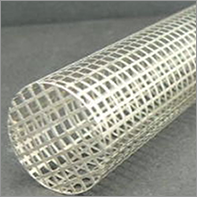

- Processing of seamless cylinders and special shapes like three dimensional shapes.

- Electroforming properties such as anti-reflection, anti-glare, and hardness.

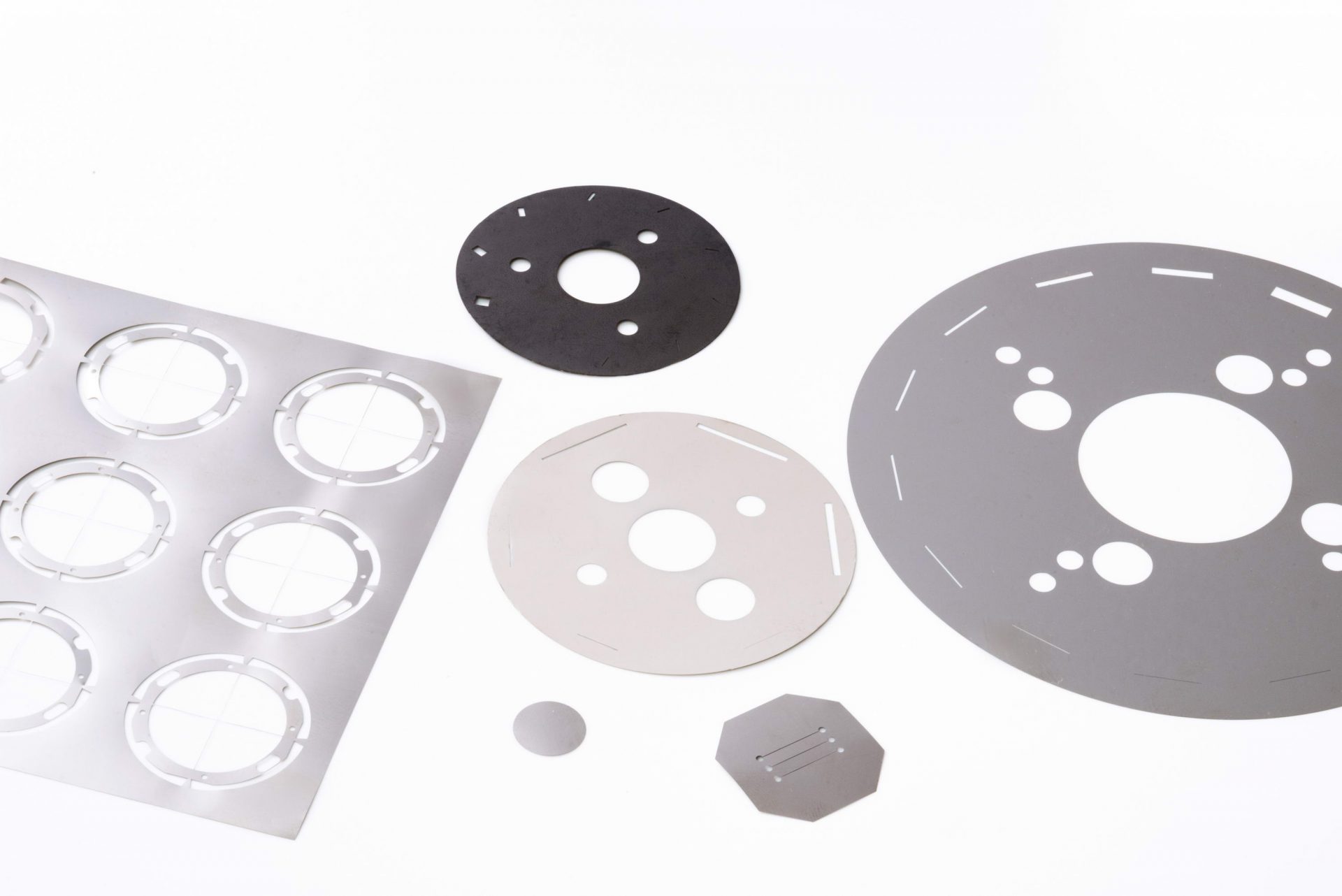

Types of Nickel electroforming

- Glossy nickel (for processing of high-precision shapes)

- Matte nickel (anti-glare effect)

- Black nickel (anti-reflection effect)

- High-hardness nickel (for components that need a hardness equal or higher than HV550)

Examples of processing

Nickel precision electroforming

Achieves processing of higher precision and accuracy than photoetching.

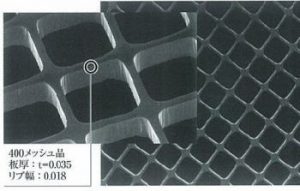

Super flat mesh

Straight processing makes it possible to create flat mesh with a vertical cross section shape. High hardness (Ref. Hv550) and excellent in durability.

3D Electroforming

3D shapes, which are difficult to achieve with etching, can be achieved with seamless electroforming.

| Example of processing | Type of electroforming | Processing | Specification |

|---|---|---|---|

| Pin hole | Glossy nickel | Straight | t=0.015 hole dia. 0.023 |

| Two step electroforming | Glossy nickel | Straight | t=0.2 |

| Mesh | Glossy nickel | Straight | t=0.01 hole dia. 0.015 |

| Porous plate | Matt nickel | Overhang | t=0.03 hole dia. 0.005 |

| Slit | Black nickel | Straight | t=0.07 hole dia. 0.042 |

Other processing (Precise hybrid etching)

MELTEC utilizes precise electroforming technology as an etching manufacturer and makes products high in precision and excellent for mass production.