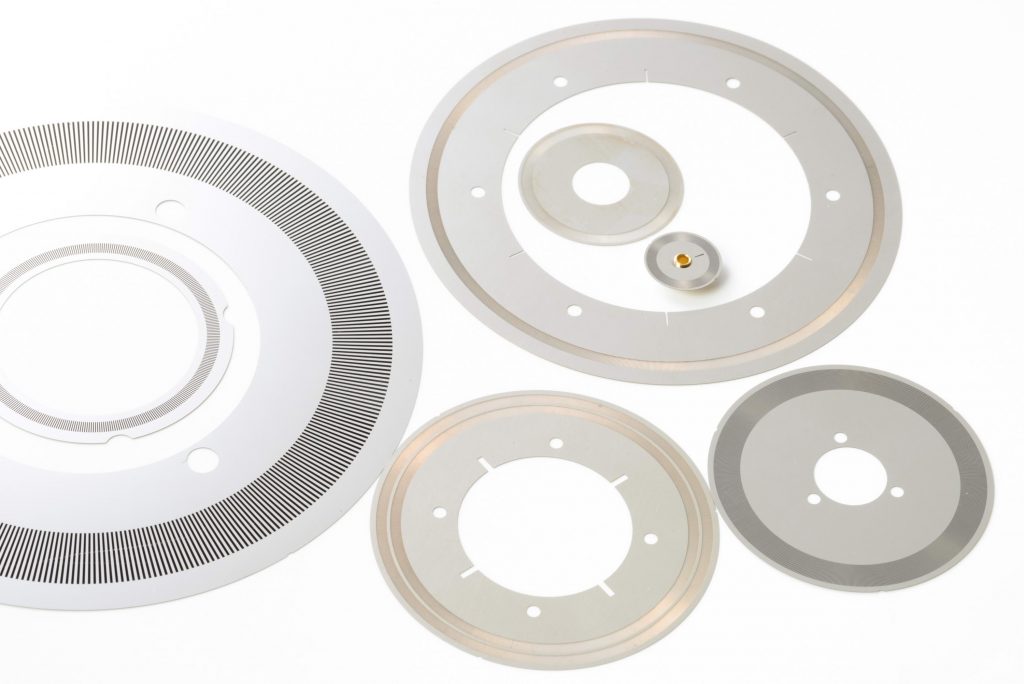

We specialize in the manufacture and sale of Optical Encoder Wheels (Optical encoder disks).

We can customize specifications such as the bar width, pitch width, tolerance, and accuracy when manufacturing an optical encoder disk to suit your needs.

Product description

Here are the descriptions of our products.

What we handle

| Material | Metal, PET film, Resin |

|---|---|

| Applicable encoder types | Incremental type, Absolute type |

| Types | Transmissive, Reflective |

| Resolution | 150, 180, 300, 360 LPI |

| Combined processing | Assembly with a hub, Reinforcement plate, Double-sided tape, Water-repellent processing(only for film) |

Click here for an explanation of the terms.

Customizable specification

| Reflectivity | Negotiable |

|---|---|

| Accuracy | Depending on Resolution of the bar (LPI or CPR) and Tolerance |

| Bar pattern | Depending on Incremental or Absolute |

| Cost | Depending on Material and Processing methods |

Click here for an explanation of the terms.

About our products

The processing materials range from PET film, metal, and high-precision metal, and we can propose the most suitable material according to the application, accuracy, and price.

Our product lineup

| Type | Style | |

|---|---|---|

| A | PET film | Transmissive/Reflective |

| B | Metal | Transmissive |

| C | Hybrid – high precision metal | Transmissive/Reflective |

| D | Mirror black | Reflective |

| E | Polycarbonate | Transmissive/Reflective |

Click on each link above for more details.

A. PET film type (Transmissive/Reflective)

Manufacturing Method: Die-cutting film sheet

This type of product is manufactured by forming fine patterns on PET film sheet material and die-cut processing.

Mass production at low cost is available.

Technical features

| Pitch tolerance | ±0.002 mm |

|---|---|

| Minimum bar width | 0.02 mm |

| Bar width tolerance | ±0.003 mm |

| Coaxiality | 0.02 mm(Transmissive style), 0.05 mm(Reflective style) |

| Inner diameter accuracy | ±0.01 mm(Transmissive style), ±0.025 mm(Reflective style) |

| Roundness | within 0.015 mm(Transmissive style), 0.02 mm(Reflective style) |

| Size change coefficient to temperature | 18µm/m°C (1.8×10-3%°C) |

| Size change coefficient to relative humidity | 10μm/m (1.0×10-3%RH) |

| Reflective style | Aluminum deposition |

| Reflectance | Over 60%(High reflective type)/Less than 10%(Low reflective type) |

Click here for an explanation of the terms.

B. Metal type (Transmissive)

Manufacturing method: Etching SUS or other metals

This type of product is manufactured by Photo-etching on stainless steel (SUS) material.

This product is not the best choice for high resolution applications, but it can be produced at a relatively low cost.

Technical features

| Base material | SUS304 planarity sheet processed by photo-etching |

|---|---|

| Minimum bar width | 0.08 mm(Minimum slit width is plate thickness × 150%) If you need less than 0.08 mm, please contact us. |

| Pitch tolerance | ±0.003 mm |

| Coaxiality | within 0.01 mm |

| Roundness | within 0.01 mm |

| Internal diameter accuracy | within 0.015 mm (when t=0.1 mm or less) |

Click here for an explanation of the terms.

C. Hybrid type – high precision metal (Transmissive/Reflective)

Manufacturing method: Precise etching on nickel clad material

This type of product is manufactured by etching a nickel clad material (Ni-Cu-Ni patented material) developed for industrial encoders.

Our etching technology used to make this product has succeeded in achieving dimensions and accuracy that were not possible with conventional etching processes.

Etching Dimension accuracy list (Transmissive style)

| Thickness (t), mm | Minimum diameter (D), mm | Tolerance, mm |

|---|---|---|

| 0.04 | 0.040 | ±0.008 |

| 0.06 | 0.050 | ±0.008 |

| 0.08 | 0.060 | ±0.008 |

| 0.10 | 0.075 | ±0.008 |

| 0.15 | 0.150 | ±0.01 |

| 0.20 | 0.200 | ±0.015 |

- The standard for the minimum slit size D is 75% of the plate thickness. (Transmissive style)

- In the case of t=0.15 mm and 0.20 mm, plate thickness is 120% of t. (Transmissive style)

Etching Dimension accuracy table (Reflective style)

| Thickness (t), mm | Minimum diameter (D), mm | Tolerance, mm |

|---|---|---|

| 0.07 | 0.04 | ±0.008 |

| 0.10 |

Technical features

| Minimum bar width(Transmissive style) | 0.04 mm (in the case of t=0.04 mm) |

|---|---|

| Minimum bar width(Reflective style) | 0.04 mm (in the case of t=0.07 mm or 0.1 mm) |

| Minimum bar tolerance | within 0.008 mm |

| Pitch tolerance(Transmissive/Reflective style) | within 0.003 mm/within 0.005 mm |

| Coaxiality | within 0.01 |

| Inner diameter accuracy | ±0.008 mm |

| Reflectiveness(High reflective type) | Over 60 % |

| Reflectiveness(Low reflective type) | Less than 10 % |

Click here for an explanation of the terms.

Other features

- Our unique hybrid material enables high precision and high accuracy etching process.

- The bar shape is sharper and the pattern reproducibility is higher, making it suitable for absolute types compared to the conventional etching method,.

- Reflective types have a high contrast between reflective and non-reflective area.

- Reflective types are less susceptible to humidity than film products.

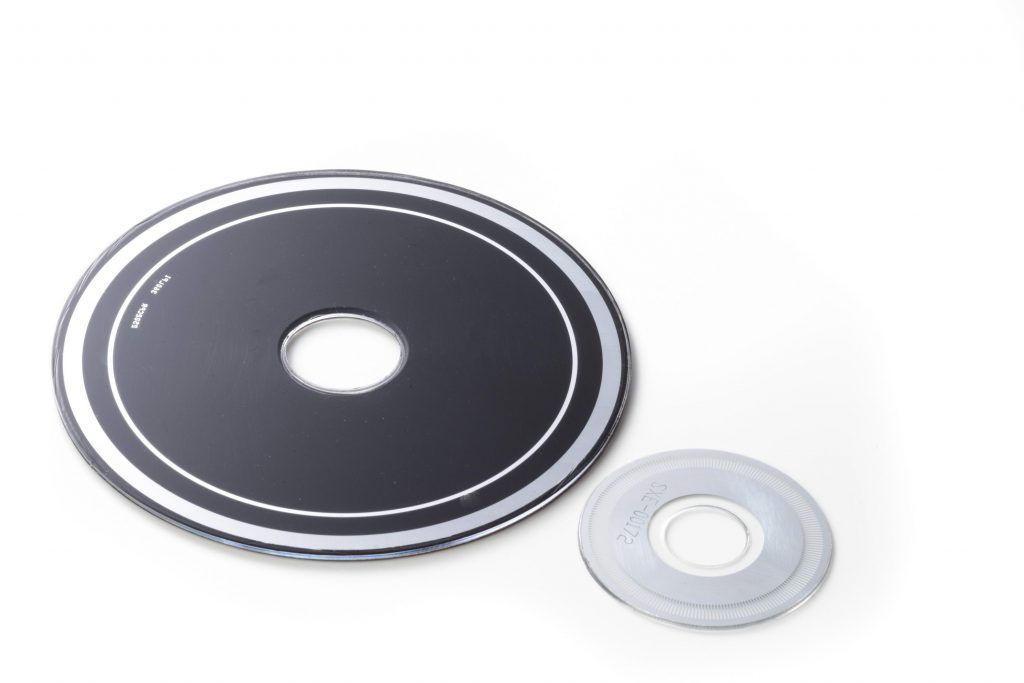

D. <Patented> Mirror black type (Reflective)

Manufacturing method: Etching metal + Low reflection black treatment

The patented and trademarked “Mirror Black®” is a reflective encoder scale made of SUS material with high-precision etching and low reflection black treatment.

This type of product has high resolution and excellent light/dark ratio (SN ratio), and provides the same performance as glass scale at a lower cost.

Technical features

| Pitch tolerance | ±0.001 mm |

|---|---|

| Bar tolerance | ±0.003 mm |

| Minimum bar width | 0.04 mm (If you need a bar width of less than 0.04 mm, feel free to contact us.) |

| Coaxiality | within 0.015 mm |

| Inner diameter accuracy | ±0.015 mm |

| Light-to-dark ratio | over 65 % |

Click here for an explanation of the terms.

Other features

- We realize high SN ratio, combining high reflectivity by SUS mirror finishing and low reflectivity by our unique matte black treatment.

- Flat structure achieves minimized unevenness of the bar pattern, leading to minimal signal noise.

E. Polycarbonate type (Transmissive/Reflective)

Manufacturing method: Stamping polycarbonate material

This type of product is manufactured by applying a thin film etching process to a polycarbonate substrate.

This product offers the same level of performance as glass encoder scales at a lower cost.

Technical features

| Heat resistance | 120 ℃ |

|---|---|

| Light-to-dark ratio | At least 70 % (Reflective type) |

Click here for an explanation of the terms.

Other features

- This product has an excellent impact resistance and is resistance to cracking.

- This product has non-transparent bars made of aluminum.

Feel free to contact us about transparent type.

Examples of Assembled Products

Assemblies with hubs

Encoder Disk Unit

Advantages of using custom encoder disks

| Accuracy | Our product can be incorporated into off-the-shelf encoders to increase accuracy. |

|---|---|

| Size | It can be installed in places where off-the-shelf encoders would not fit. |

| Production | You can choose from a single prototype to mass production. |

| Cost | Since the material and precision can be determined, the cost can be kept to a minimum. |

Usage of our products

- Industrial robots and positioning servos

- Automation of production plants

- Automotive industry

- OA equipment

- Machine tools

- Measuring instruments

Summary

Click here for an explanation of the terms.

| Type\Specification | Material | Minimal Bar width, mm | Bar width tolerance, mm | Pitch tolerance, mm | Inner diameter accuracy, mm | Coaxiality |

| Film (Transmissive style) |

PET | 0.02 | ±0.003 | ±0.002※ | ±0.01 | 0.02 |

| Film (Reflective style) |

PET | 0.02 | ±0.002 | ±0.002※ | ±0.025 | 0.05 |

| Metal (Transmissive style) |

SUS | 0.08 (in the case of t=0.05) | ±0.015 | ±0.003 | ±0.015(in the case of t<0.1) | more than 0.01 |

| Hybrid (Transmissive style) |

Ni-Cu-Ni | 0.04 (in the case of t=0.04) | ±0.008 | ±0.005 | ±0.008 | 0.01 |

| Hybrid (Reflective style) |

Ni-Cu-Ni | 0.04 | ±0.008 | ±0.005 | ±0.008 | 0.01 |

| Mirror black (Reflective style) |

SUS | 0.04 | ±0.003 | ±0.001 | ±0.015 | 0.015 |

| Polycarbonate (Reflective style) |

Aluminum +Polycarbonate |

0.01 | ±0.003 | ±0.002 | Please contact us for details. | |

| Type | Function |

| Film (Transmissive/Reflective styles) |

Size change coefficient to temperature: 18µm/m°C(1.8×10-3%°C) Size change coefficient to relative humidity: 10μm/m(1.0×10-3%RH) Aluminum vapor deposition type with 60% or more of high reflection, 10% or less of low reflection (Reflective type) |

| Metal (Transmissive style) | Good corrosion resistance and durability |

| Hybrid (Transmissive style) |

High accuracy and high resolution 60% or more of high reflection, 10% or less of low reflection (Reflective type) |

| Mirror black (Reflective style) |

High accuracy, high resolution, good dark/light ratio, good SN ratio 60% or more of high reflection, 10% or less of low reflection (Reflective type) |

| Polycarbonate (Transmissive/Reflective styles) |

Heat resistance:120°C 78% or more of high reflection, 10% or less of low reflection (Reflective type) |

Need more information?

Contact us to request pricing, availability and customization options